Building My Workshop

Building my custom 20'x22' workshop

Site Prep

Before the actual construction could begin, trees and stumps had to be removed along with the backside of the pool fence. Next, string lines were setup to show where the outer edge of the subfloor would be. Then markings were made to identify where holes needed to be dug for the spread footings.

Figure 1. Tree and stump clearing

Figure 2. Tree and stump clearing

Figure 3. Tree and stump clearing

Figure 4. Privacy fence removal

Figure 5. Privacy fence removal

Figure 6. Privacy fence removal

Construction

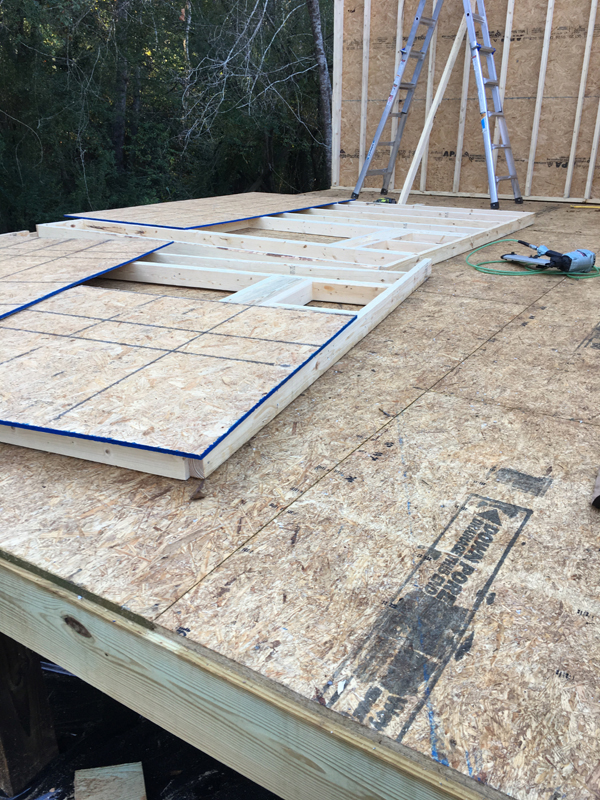

Almost all of my building materials were purchased from MarJam Supply and the metal roofing was purchased from a roofing supply company. The first step was to dig 2 foot square spread footings to support the 6x6 posts that will support the floor joists. After the spread footings were inspected, the footings were poured and a bolt was placed in the center of the footing to attach a plate to the footing. The posts were then set and attached to the plates that were bolted to the footings. The floor joists were then built and inspected. After the inspection, the subfloor (4x8x3/4 plywood) was then built. The walls were then built on the subfloor and then lifted into place. After the walls were built, OSB sheathing was placed on the exterior walls and wrapped. Next, the trusses were built and raised into place. 2x4 purlins were then placed to support the metal roof. The doors and windows were installed and then the vinyl siding was attached. Wire screen was attached in the sofit to prevent birds and insects for getting into the workshop. The final two steps were to build a privacy fence up to the workshop to protect the pool and to build a retaining wall and backfill up to the floor joist on the garage door side.

Figure 7. Spread footings and batter boards

Figure 8. Spread footings and batter boards

Figure 9. Spread footings and batter boards

Figure 10. Spread footings

Figure 11. Spread footing with wire mesh

Figure 12. Spread footings and batter boards

Figure 13. Spread footings and batter boards

Figure 14. Poured spread footing with anchor bolt

Figure 15. Setting 6x6 posts and outer support beams

Figure 16. Setting 6x6 posts and outer support beams

Figure 17. Setting 6x6 posts

Figure 18. Floor joist support set on 6x6 posts

Figure 19. 6x6 posts

Figure 20. 6x6 posts

Figure 21. 6x6 posts bracket attached to a spread footing

Figure 22. 6x6 posts bracket attached to a spread footing

Figure 23. Floor joist support set on 6x6 posts

Figure 24. Floor joists being set

Figure 25. Floor joists being set

Figure 26. Floor joists being set

Figure 27. Laying the plywood flooring

Figure 28. Laying the plywood flooring

Figure 29. Plywood floor is complete

Figure 30. Setting walls

Figure 31. Cutting/materials area

Figure 32. Setting walls

Figure 33. Setting walls

Figure 34. Building walls before lifting them into place

Figure 35. Setting walls

Figure 36. Setting walls

Figure 37. Setting the garage door header

Figure 38. Hanging OSB sheathing

Figure 39. Hanging OSB sheathing

Figure 40. Hanging OSB sheathing and hanging house wrap

Figure 41. Hanging house wrap

Figure 42. Truss spacing with 2x4 purlins

Figure 43. Trusses with 2x4 purlins

Figure 44. Metal roof installed

Figure 45. Metal roof installed

Figure 46. Installing the metal roof on the backside of the workshop

Figure 47. Metal roof is complete

Figure 48. Installing windows and fascia board

Figure 49. Installing the entry doors and garage door

Figure 50. Installing the garage door

Figure 51. Rafter area

Figure 52. Facia, entry door, and garage door complete

Figure 53. Facia, entry door, and garage door complete

Figure 54. Installing vinyl siding

Figure 55. Installing vinyl siding

Figure 56. Installing vinyl siding

Figure 57. Installing vinyl siding

Figure 58. Installing vinyl siding

Figure 59. Installing vinyl siding

Figure 60. Vinyl siding is complete

Figure 61. Building the privacy fence and adding rock

Figure 62. Building the retaining wall

Figure 63. Building the retaining wall

Figure 64. Building the retaining wall

Figure 65. Building the retaining wall

Figure 66. Backfilling

Figure 67. Trench for drain pipe

Figure 68. Retaining wall with backfill

Figure 69. Retaining wall with backfill

Electrical

The electrical was ran from a 100-amp double-pole breaker in my main panel to a 125-amp sub panel in the workshop. I used direct burial wire (4-4-4 Vassar Aluminum Triplex URD Direct Burial Cable) that was placed in a 3' trench. The wire was #4 and 3-conductor (2 hots and a netual) that is rated for 123-amps. Both end points are connected to a 100-amp double-pole breaker. The 123-amp rating is plenty to compensate for the voltage drop of my 100' run (panel to panel). I'm only going to power a few LED lights and a few wall outlets so 100-amp breakers were plenty. I was planning to go with 80-amp breakers but the 100-amp breakers were cheaper. I then ran three legs (leg #1 - for three electrical outlets, leg #2 - for two outlets to power the LED lights, and leg #3 - a single electrical outlet). Conduit was used to bring the wire from the 3' trench, through the subfloor and seal plate, to the bottom of the sub panel with the three legs exiting the top of the panel. I was able to do all this myself and hire a DIY-friendly electrician to pull my permit and inspect my work before having the city inspect it.

Created by Robert Keith · © 2024